Application parameters flow spread / stiffening behavior

Flow spread and stiffening behavior are among the most important rheological parameters for fresh construction material mixtures, particularly for mortar and concrete. They characterize the flow behavior and workability of these materials and are therefore crucial for construction applications.

The flow spread is a standard value to determine the consistency of a fresh building material mixture. It is determined by a standardized test in which the material is caused to flow on a defined surface after removing a test mold. The resulting flat cake is measured, with a larger spread indicating a softer consistency. Different consistencies are required for different applications - from stiff concrete for road construction to flowing mixtures for thin-walled or heavily reinforced components. The precise adjustment of the spreadability is achieved through the water-to-binder ratio and the use of additives.

In contrast, the stiffening behavior describes the temporal change in the workability of a construction material mixture after mixing. It is a measure of the speed at which a material loses its initial flowability and transitions into hardening process. An ideal stiffening behavior enables a sufficiently long processing time, followed by rapid development of strength after installation. Factors such as ambient temperature, type of cement, admixtures and water content significantly influence this parameter. The measurement of stiffening behavior can be carried out, for example, using ultrasonic methods, where the sound speed in the material increases with progressing hardening, allowing for conclusions about the solidification process.

n practice, both parameters must be carefully coordinated. An optimum spread flow ensures good pumpability, easy placement, and complete filling of the formwork, while controlled stiffening behavior ensures efficiency on the construction site and allows for early strengthss. Deviations from the specified values may indicate problems in the composition of the mix, raw materials or production process and must be corrected immediately in order to guarantee the required properties of the finished component.

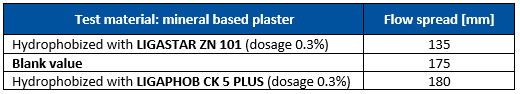

Both parameters can be precisely influenced by the use of oleochemical additives. Our metal soap LIGASTAR ZN 101 enables a significant reduction in the flow spread, while our specially developed combination product LIGAPHOB CK 5 PLUS increases it. In the presence of alkaline soaps, the stiffening behavior is noticeably accelerated. On the other hand, natural acids such as tartaric or citric acid often serve as effective retarders.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/d/csm_Produktbild_Pulver_ebb2138f79.webp)