Liquid Hydrophobing Agents for Concrete

Concrete is one of the most important and widely used construction materials worldwide. Its robustness and versatility make it indispensable, but without proper protection, even this resilient material is exposed to the influences of weather, moisture, and environmental pollution. When water penetrates the porous structure, it transports salts and chlorides to the reinforcement, initiating undesirable corrosion processes. Freeze-thaw cycles cause material spalling, while moisture leads to efflorescence and provides an ideal breeding ground for algae, fungi, or other microorganisms. The consequences extend far beyond aesthetic impairments and manifest as severe structural damage, necessitating extensive and costly repair measures. Therefore, timely and properly executed surface protection is not an optional extra, but an investment in long-term value preservation.

The particular challenge in concrete protection arises from the fact that it is mixed and transported in liquid form, making the use of liquid water repellents almost indispensable. Silanes and siloxanes, as well as oleochemical additives, have proven effective in reliably protecting the building material from moisture and significantly extending the lifespan of structures. Oleochemical additives penetrate deep into the concrete pores and establish a water-repellent barrier at molecular level. Their crucial advantage over film-forming sealants lies in the fact that the pore structure remains open, allowing the concrete to retain its natural vapor diffusion ability. This way, moisture can escape from the inside while the intrusion of water from the outside is effectively prevented. This intelligent protective effect preserves the building material in the long term, significantly extends maintenance intervals, and simultaneously maintains the authentic, unchanged appearance of concrete.

A particularly forward-looking aspect of oleochemical additives is the significantly improved recyclability of treated building materials. While silane-modified materials are often difficult or impossible to reintegrate into the recycling loop, oleochemically treated materials allow for seamless material recycling. This ideally corresponds with the increasing demands of the Circular Economy in the construction sector and contributes to resource conservation as well as minimizing construction waste.

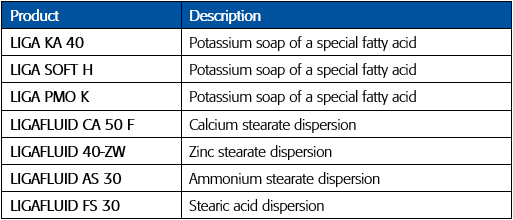

In the field of oleochemistry, particularly metal soap dispersions, alkaline soap solutions, and fatty acid suspensions are used. These systems combine hydrophobic properties with a liquefying effect that leads to a reduction in capillary structure. As a result, the following products are optimally suited for this demanding application area: